WELDING-

Oxy-Fuel Cutting is a process that uses a torch to cut metal by heating it with a flame from oxygen and fuel gas, then injecting pure oxygen to oxidize and blow away the molten metal. It’s mainly used for cutting carbon steel.

Oxy-Fuel Cutting offers simple operation, low equipment cost, and the ability to cut thick steel efficiently. It’s widely used for construction, repair, and metal fabrication due to its portability and suitability for outdoor or heavy-duty cutting tasks.

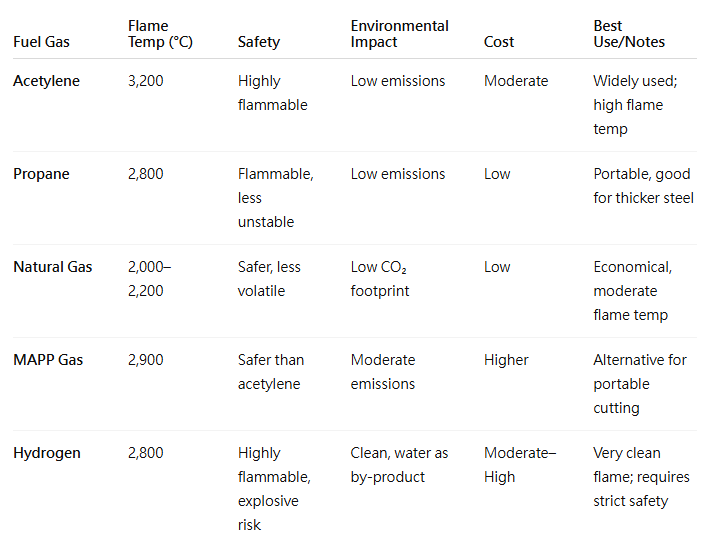

Oxy-Fuel Welding joins metals like carbon steel, alloy steel, cast iron, aluminum, and magnesium using a torch with oxygen and fuel gas (e.g., acetylene). The flame, reaching about 3,200°C, melts the metal edges to form a weld. Three flame types—neutral, oxidizing, and carburizing—are used depending on the metal and application.

- Versatile: Can weld a wide range of metals, including steel, cast iron, aluminum, and magnesium.

- Portable: Equipment is simple and can be used in remote or outdoor locations.

- Low Cost: Affordable setup compared to electric welding methods.

- Precise Control: Flame adjustment allows fine control for delicate or detailed work.

- Essential for Repairs: Ideal for maintenance, fabrication, and on-site metal joining where other welding methods are impractical.

Oxy-fuel cutting is ideal for thick carbon steel and outdoor use due to portability.

Plasma and laser cutting are faster, more precise, and suitable for thinner metals or automated production, but require more expensive equipment and power.

- Fuel Gas Cylinder – Supplies gas like acetylene, propane, or natural gas.

- Oxygen Cylinder – Supplies pure oxygen for combustion and cutting.

- Regulators – Control the pressure of oxygen and fuel gas from the cylinders.

- Hoses – Deliver gases from the cylinders to the torch safely.

- Torch – Mixes oxygen and fuel gas and directs the flame onto the metal.

- Cutting Tip/Nozzle – Shapes the flame and oxygen jet for cutting.

- Striker or Igniter – Used to light the torch safely.

- Protective Equipment – Includes helmets, goggles, gloves, earmuffs, and flame-resistant clothing for operator safety.

SAFETY-

Personal Protective Equipment (PPE) refers to gear worn to minimize exposure to hazards that can cause serious workplace injuries or illnesses. These hazards may include physical, chemical, electrical, mechanical, or biological risks. PPE includes items such as gloves, safety glasses, helmets, ear protection, respirators, safety footwear, high-visibility vests, coveralls, and full-body suits.

Before purchasing PPE, assess the workplace hazards and identify the specific risks that need protection. Choose PPE that meets relevant safety standards and fits the user properly. Also, consider comfort, durability, compatibility with other equipment, and ease of maintenance or replacement.

Yes. PPE must be tested and inspected to ensure it meets safety standards and provides proper protection. Regular inspections should be carried out before and after use to check for damage, wear, or defects. Damaged or expired PPE must be replaced immediately to maintain safety compliance.

PPE should be stored in a clean, dry, and well-ventilated area away from direct sunlight, chemicals, and extreme temperatures. It must be kept organized to prevent damage or contamination. Always follow the manufacturer’s instructions for proper storage to maintain the equipment’s effectiveness and lifespan.

PPE should be replaced whenever it becomes damaged, worn out, contaminated, or no longer provides adequate protection. The replacement frequency depends on the type of equipment, usage conditions, and manufacturer’s recommendations. Regular inspection helps determine when replacement is necessary to ensure continued safety.

The life expectancy of safety helmets depends on the material, usage, and environmental conditions. Generally, plastic or fiberglass helmets last about 3–5 years, while helmets exposed to extreme conditions (sunlight, chemicals, heat) may need replacement sooner. Manufacturers’ guidelines and regular inspections should always be followed to ensure maximum protection.